Today, we will break down the "skeleton, nerves, muscles, and brain" of a sectional door to see how they work in synergy, ensuring decade-like day-to-day stability and reliable operation!

A sectional door is a high-performance industrial door guided by a precision track and utilizes a torsion spring balancing system or an electric drive system to achieve vertical movement. When opened, the door rises smoothly along a pre-set track to the top and descends precisely to the ground to seal when closed. It offers excellent sealing, wind resistance, and energy efficiency. For example, the Kuailian insulated sectional door utilizes a modular design concept, comprised of four core systems:

1. Door system

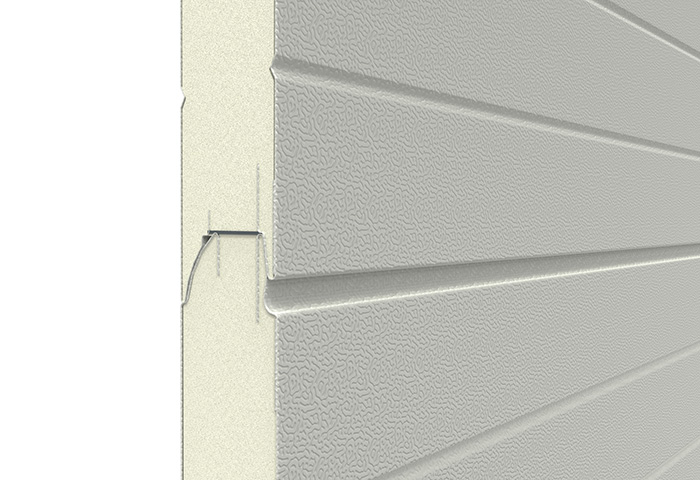

The door panel adopts a sandwich composite structure, with the outer layer being a high-strength aluminum alloy or steel outer panel, which is formed in one step on the German Hennecke continuous automatic production line; the PE coating is processed through a two-coating and one-bake process (film thickness ≥ 25μm).

The interior is filled with Huntsman polyurethane foam material from the United States, which uses a fluorine-free polyurethane high-pressure foaming process. The foaming is uniform and dense, with a closed-cell rate ≥ 90% and a density of 48±2kg/m³; the environmental performance complies with RoHS standards, the heat transfer coefficient K=1.1W(㎡.K), and it has excellent thermal insulation and flame retardant properties.

The inner/outer panels are formed into a whole through a structural bite design to enhance the overall strength and thermal insulation.

1.1 Door panel connection method

The door panels are connected by hinges and equipped with self-lubricating bearings to ensure smooth operation and structural stability. The standard door panel height is 500mm (with a tolerance of ±0.5mm), and customization is available within a range of 200-800mm. High-quality sealing strips are used at the joints to ensure a good seal.

2. Track system (track + auxiliary rail)

2.1 Main Track

The track system of the main track industrial sectional door is made of galvanized steel plate (base thickness ≥ 2.0mm) with an anti-corrosion surface treatment. The top mounting structure guides the door body to slide smoothly along the track, achieving vertical upward or turning lifting, which can maximize the use of the vertical space in the warehouse area. At the same time, it adopts a modular and detachable design. All connection nodes use standard fasteners and can be disassembled without welding, which significantly simplifies subsequent maintenance operations. The replacement time of a single track section can be controlled within 30 minutes.

2.2 Auxiliary track

The auxiliary rails are used to assist in guiding the door, ensuring that it does not deviate or get stuck during operation. Bolts are used for connection, avoiding traditional welding and facilitating replacement and maintenance.

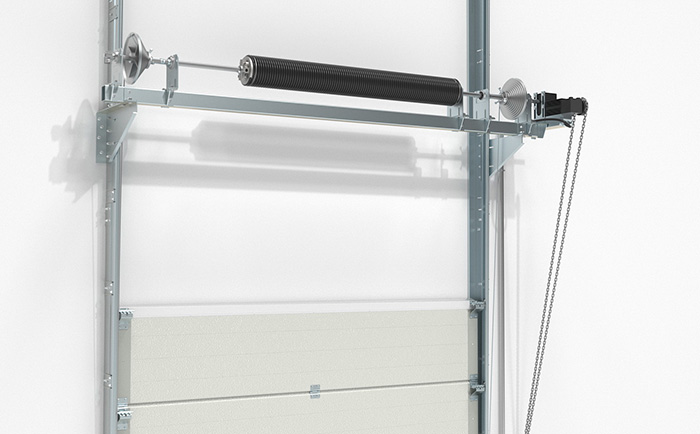

3. Torsion spring balance system

The torsion spring balancing system is the core mechanism that ensures the smooth operation of the door. Its operating principle is based on the dynamic conversion of elastic potential energy and gravitational potential energy. It consists of torsion springs, wire ropes, pulleys, torsion spring shafts, support frames, and other components that balance the door.

3.1 Torsion Spring

The FastLink torsion spring is made of 55CrSi high-strength spring steel, with a surface treated by shot blasting and electrophoresis, and a service life of ≥30,000 cycles.

3.2 Balancing Principle

The sectional door achieves dynamic balancing through the elastic force of the torsion springs, with a balancing accuracy of ±5%. The door can be maintained statically in any position, making it lightweight, stable, and labor-saving during operation.

3.3 Safety Design

A wire rope anti-break device effectively prevents the door panel from accidentally sliding down, avoiding safety accidents. In the event of a power outage, the door can be opened via a manual chain without the need for additional tools.

4. Drive and control system

4.1 Motor system

The high-precision absolute encoder electronic limit system uses digital signals to directly feed back the real-time position of the door body. Compared with traditional mechanical limiters, it has higher stability and reliability and eliminates the "limit run" phenomenon. The system supports direct parameter setting through the control box, without the need for physical adjustment of the limit block, improving debugging efficiency by more than 80%, while ensuring safe locking of the limit position.

4.2 Control box

The intelligent control system for industrial sectional doors is equipped with an LCD that can display key parameters such as fault codes, door operating status (open/closed/stopped), and operation times in real time. The system integrates an RS485 communication interface, supporting remote fault diagnosis and maintenance management via the Internet of Things platform, significantly improving equipment operation and maintenance efficiency. In terms of control methods, it provides a variety of intelligent operation options, including button control, wireless remote control, geomagnetic induction, and linkage control with the fire protection system, realizing a comprehensive intelligent door control solution.

4.3 Safety protection device

The FastLink sectional door utilizes a new generation of wireless airbag protection, eliminating the traditional spiral cable connection method. This not only eliminates cable entanglement but also reduces the risk of protection failure due to accidental pulling. The system also comes standard with a fire alarm interface that automatically raises the door to an escape height of 50 cm above the ground upon receiving a fire signal. It also integrates intelligent electrical protection features, including power phase loss protection and motor stall protection, among other safety mechanisms. These innovative designs effectively reduce the need for height-related work during after-sales service, significantly improving equipment safety and ease of maintenance.

Industrial sectional doors achieve efficient and smooth vertical lifting movement through the precise collaboration of four core components: door system, track system, balance system, and drive control system. They are an important portal solution in modern and efficient logistics and production environments.