In such a high-standard manufacturing system, logistics efficiency and production safety cannot be compromised—this is the key to the collaboration between Fastlink Door and Ideal Auto. Our customized day and night combination doors, mechanical dock shelter, and hydraulic dock leveler, as key logistics infrastructure, not only perfectly meet the stringent demands of automotive manufacturing but also have earned acclaim for their highly customized capabilities, efficient delivery, and intelligent service.

The insulated sectional door and PVC high-speed door, a classic combination door system, utilize a double-layer structure of "exterior insulated sectional door + interior PVC high-speed door," achieving "double door synergy and multiplied efficiency," perfectly addressing the complex demands of temperature control, cleanliness, and logistics efficiency in new energy vehicle manufacturing.

Flexible activation and efficient passage

To accommodate varying traffic needs throughout the day, PVC high-speed doors are used during daytime hours to enable efficient passage, while insulated sectional doors are deployed at night to provide enhanced security protection and anti-theft functions. This flexible approach leverages the complementary advantages of both door types, making it particularly suitable for environments such as paint shops and battery assembly workshops.

Insulated sectional door

Insulated sectional doors block external heat, and the PVC curtain closes quickly, reducing air exchange between indoor and outdoor spaces. This significantly reduces building energy consumption compared to single-door structures. The panels of these insulated sectional doors utilize

double-layer aluminum panels and a high-density polyurethane insulation layer, achieving a thermal conductivity of ≤0.025W/(m·K). High-quality sealing strips are installed around the door and between the panels, ensuring an excellent seal throughout the entire door.

- High-intensity protection

The Changzhou Linjiang area is prone to typhoons. These insulated sectional doors offer wind pressure resistance up

to level 12 and salt spray corrosion resistance for over 1,000 hours, making them suitable for the humid climate of the Yangtze River Delta. The door panel color can be customized to meet customer requirements and can be integrated with the factory security system, adding a touch of elegance to the complex.

PVC high-speed door (interior high-speed door)

PVC high-speed doors achieve an extremely fast response speed of 1.5m/s, effectively isolating the workshop from dust and noise, meeting the cleanliness requirements of an ideal automotive workshop. Optional transparent PVC windows provide both daylighting and safety, ensuring more efficient forklift access.

Mechanical dock shelter

- Environmental adaptation, core protection

As the "first line of defense," the mechanical dock shelter is a component of the overhead door, fulfilling a key role in providing protection, safety, and extending the door's service life. It effectively resists external physical impacts, such as vehicle collisions and scratches from heavy objects, preventing deformation and damage to the door's surface coating. It protects against wind, rain, dust, and air flow, effectively sealing the space between vehicles and the warehouse, improving the working environment, energy conservation, and overall warehouse operation.

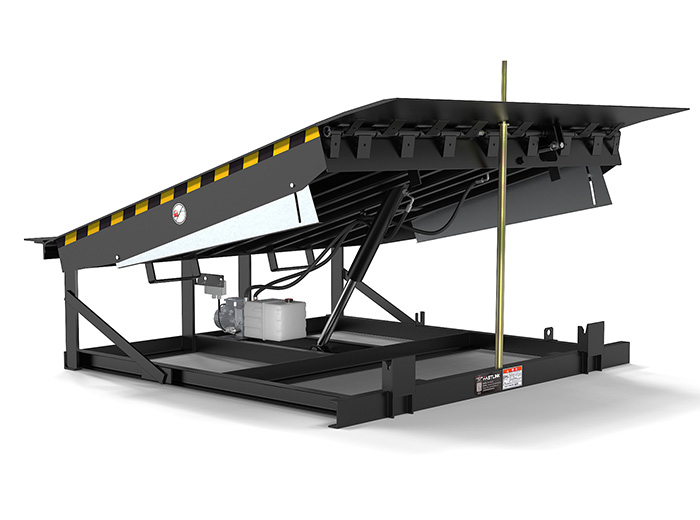

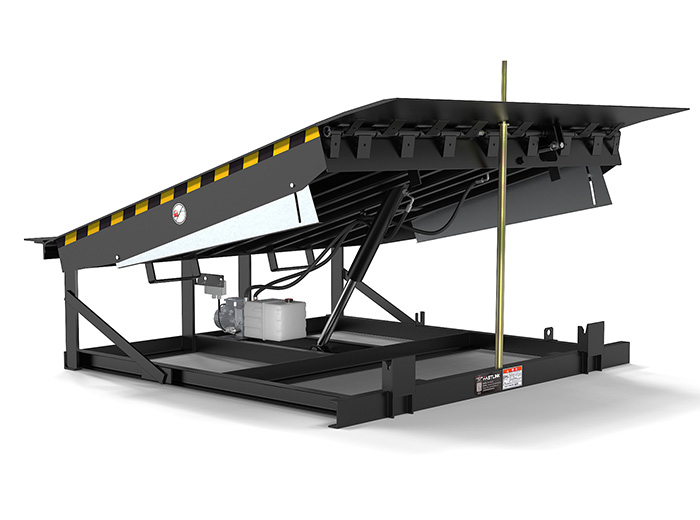

Hydraulic dock leveler

- Efficient loading and unloading, safe and worry-free

Seamless truck docking: Precisely adjustable height ensures error-free loading and unloading of Li Auto components, significantly boosting operational efficiency.

Slip-resistant & durable: The platform is constructed with a high-strength checkered steel plate, providing reliable anti-slip performance even in rainy conditions and a load-bearing capacity exceeding 10 tons, far surpassing industry standards for durability.

Why is a door so important to Ideal Auto?

An industrial door serves as a critical functional component for an automotive manufacturing workshop, integrally linking safety, processes, logistics, and operations. Its significance far exceeds that of a conventional protective barrier or simple partition. It ensures energy efficiency and stable workshop humidity through insulated sectional doors, maintains the cleanliness of precision component assembly areas with high-speed doors—thereby providing a stable environmental foundation for key automotive manufacturing processes—and incorporates high-sensing-speed designs compatible with AGVs and forklifts to eliminate logistics bottlenecks. Selecting a more professional industrial door supplier safeguards production continuity and operational efficiency across multiple dimensions, making it an indispensable element of the automotive manufacturing infrastructure. Follow Fastlink Door for comprehensive industrial door solutions.