Five Pain Points of Traditional High-Speed Doors

1. Short Lifespan of Tension Springs and High Replacement Costs

Traditional balance systems rely on tension springs with a lifespan of only about 50,000 cycles, requiring approximately 10 replacements over the door’s lifecycle. Frequent use leads to spring fatigue, increasing motor overload risks, maintenance costs, and operational noise.

2. Outdated Track Design and High Operating Noise

Most products feature discontinuous tracks with abrupt radius changes, resulting in significant gaps between rollers and tracks. This causes noticeable noise during operation.

3. Poor Thermal Insulation of Door Panels

Common 40mm-thick panels are often manually foam-filled, leading to uneven insulation and lack of thermal break design, resulting in substantial energy loss.

4. Difficult Maintenance and Disrupted Production Continuity

Closed welded track structures prevent individual panel removal, requiring full track disassembly for repairs. This increases maintenance costs and poses operational risks.

5. Low Reliability of Electrical Systems

On-site wiring and manual crimping connections are prone to issues like poor contact, leakage, and short circuits, creating significant safety hazards.

Core Advantages of Fastlink Spiral High Speed Doors

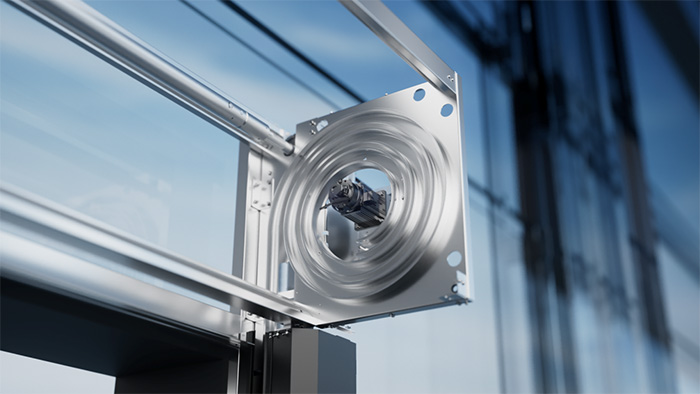

1. High-Speed Silent Operation: Archimedes Dual-Turbine Track Design

Utilizing an Archimedes curve track, the door operates with minimal resistance, achieving smooth motion and speeds up to 2.5 m/s with near-silent performance. The non-contact, friction-free design during rapid opening and closing extends the door’s lifespan.

2. Maintenance-Free Counterweight System: Eliminating Frequent Spring Replacements

A dynamic balance system replaces traditional tension springs, with belt life exceeding 1 million cycles, significantly reducing long-term costs. Counterweights ensure even force distribution, while polymer guide channels eliminate noise.

3. High-Efficiency Insulated Panels: Thermal Break Design for Energy Savings

Panels are manufactured using German Bayer-Hennecke automated production lines, available in 42mm and 80mm thicknesses. Featuring thermal break design, the 42mm panels achieve a U-value of only 1.1 W/(㎡·K), ideal for cold storage and cleanroom environments.

4. Openable Track Design: Easier and Safer Maintenance

Segmented removable tracks allow individual panel replacement without full disassembly, simplifying maintenance, reducing downtime, and enhancing operational efficiency.

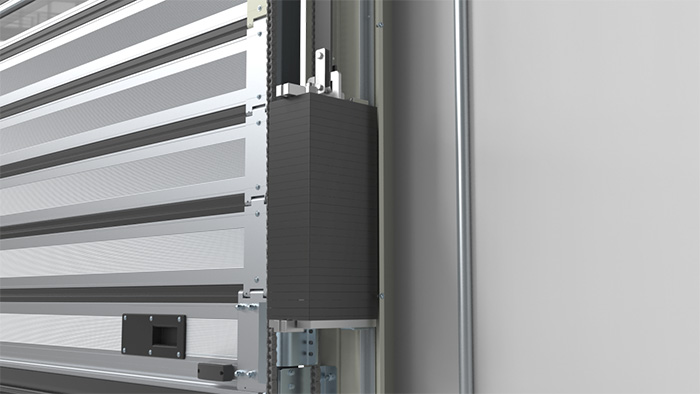

5. Intelligent Control System: IoT Integration and Remote Management

A self-developed IP65-rated control system with an LED display shows operational cycles and fault codes. It features power-off memory, automatic recovery after manual operation, and motor overload/overcurrent protection, with IoT connectivity.

6. Hardware Accessories: Ensuring Long-Term Durability

Hinges and brackets are made of 6mm-thick electrophoretic-treated aluminum alloy, resistant to rust. Fasteners use Dacromet plating to prevent galvanic corrosion. Bushings are made of wear-resistant PEEK for noise reduction, while imported TPU rollers offer a lifespan exceeding 1 million cycles.

7. Flexible Installation Options: Adapting to Various Spaces

Available in spiral, elliptical, and smooth lifting styles to suit different spatial requirements. Multiple opening modes (induction sensors, radar sensors, remote control, etc.) cater to commercial and residential needs.

Smart Manufacturing System: Ensuring Consistent Quality

Fastlink operates an industry-leading automated production base equipped with German Bayer-Hennecke automated panel production lines and high-precision bending equipment (accuracy: 0.1mm). This enables in-house R&D and production of key components like panels and curved tracks. Through full-process automation and precision manufacturing, Fastlink ensures rigorous quality standards while supporting customized solutions for factories, warehouses, and logistics centers, streamlining production and delivery for efficient customization.

The Fastlink Spiral High-Speed Door is more than just a door—it's an intelligent access solution that combines precision design with a reliable structure, fundamentally addressing the pain points of traditional high-speed doors. In today’s era of manufacturing transformation and logistics efficiency innovation, choosing a truly efficient, smart, and reliable door is paving the way for sustainable business gr