What is an Industrial Sectional Door?

Also known as an industrial lift door or sectional overhead door, the industrial sectional door is specifically designed for industrial buildings. Equipped with a dynamic balancing system, the door operates smoothly along guide rails via rollers on both sides, enabling stable opening and closing. Fastlink sectional doors are mainly divided into two types: insulated doors for ambient storage and insulated doors for cold storage.

1. Clarify the Usage Scenario

Determining the type of sectional door based on the scenario is the foundational step in selection.

Dry Storage: In standard environments such as logistics warehouses or industrial workshops, factors like insulation, wind resistance, sealing, and stability must be considered. Users can prioritize insulated sectional doors with 42mm thick panels, which meet general energy-saving needs while being lightweight. The main rails of the door feature a specially bent design to prevent rollers from dislodging, ensuring better wind resistance.

Cold Chain Scenarios: The primary challenges in cold storage are condensation prevention, thermal bridge elimination, and low energy consumption. Insulated sectional doors with 65mm–75mm thick panels are recommended. High-density polyurethane panels combined with thermal break aluminum profiles effectively block heat transfer. Insulated rail seals and dual sealing strips prevent thermal bridging. Heated windows with integrated heating films address condensation issues in low-temperature environments. Shot-peened and electrophoresized torsion springs are suitable for humid conditions, preventing rust and reducing maintenance needs.

2. Focus on Material and Structure

Different structures and materials directly affect the door’s lifespan and maintenance costs.

Door Panels: Aluminum alloy panels are recommended for their lightweight and excellent corrosion resistance. Fastlink utilizes a Bayer Hennecke continuous production line for panel manufacturing, filled with Huntsman polyurethane to ensure insulation performance, suitable for energy-saving scenarios like dry storage and cold chain.

Guide Rails: Key considerations for rails include material and design. Rails made of 2.0mm galvanized steel with a special anti-wind edge design prevent roller dislodgment. The bolted connection between main and auxiliary rails facilitates maintenance and replacement, reducing after-sales costs.

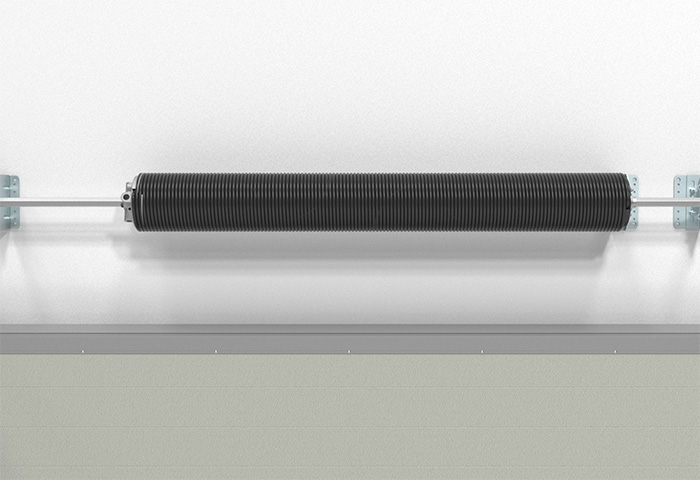

Torsion Springs: Fastlink uses 55CrSi high-strength spring steel torsion springs, which are smooth, hard, corrosion-resistant, and minimize long-term maintenance costs, making them suitable for humid environments like coastal areas.

3. Determine the Lifting Method

The lifting method should be selected based on door opening dimensions, lintel height, and installation space constraints to avoid operational issues due to spatial mismatches.

Standard Lift: Lintel height h=450/530mm, the conventional choice for industrial plants, suitable for most standard openings.

High Lift: Lintel height h>630mm, maximizes door opening height, ideal for scenarios requiring high clearance.

Vertical Lift: Lintel height h>H+600mm, suitable for large factory doors or special requirements, requiring sufficient overhead space.

4. Prioritize Core Requirements

Choosing the right sectional door requires focusing on core needs, avoiding over-specification or neglecting key performance aspects.

Energy Efficiency: Insulation and sealing are critical. Fastlink sectional doors achieve a thermal transmittance of 0.92W/(㎡·k). A comprehensive sealing design includes EPDM seals at the bottom, sides, top, and between panels, along with co-extruded soft-hard seals between rails and panels, ensuring full sealing and reducing energy loss.

Wind Resistance: Select based on regional wind conditions. Fastlink doors offer excellent wind resistance and can withstand strong winds. Optional wind bars are available: galvanized steel wind bars are standard for openings W<6000mm, while aluminum alloy wind bars are standard for W≥6000mm.

Safety: In busy logistics environments, safety is essential. Fastlink doors are equipped with comprehensive protections, including a steel cable breakage prevention device, torsion spring breakage protection, wireless safety edges, and industrial AC motors with electronic limit switches for low failure rates.

Smart Management: Enhancing convenience and management efficiency is also important. Fastlink’s self-developed integrated smart control system includes an LED display showing operation counts and error codes. Fire linkage enables automatic opening during emergencies. IoT-enabled remote diagnostics allow integrated door and platform control. Variable frequency operation ensures smoother, quieter performance.

In summary, selecting a sectional door requires considering the usage scenario, core needs, and compatibility with materials, structure, and lifting methods. A well-matched solution not only maximizes the space-saving advantages of sectional doors but also strengthens operational reliability for industrial production and logistics warehousing.