I. Clarify the primary sealing objectives

Thermal Insulation (Cold & Heat): Dock seals and shelters act as "temperature guardians," connecting the truck trailer to the warehouse. In cold environments, they effectively block cold air intrusion and minimize heat loss—particularly essential in cold storage and temperature-controlled warehouses. Like a thick blanket, they maintain stable temperatures, enabling significant energy savings.

Impact Protection: In high-frequency loading zones, they serve as "soft cushions," absorbing collision impact through flexible materials to prevent damage to both vehicles and dock doors. This is especially critical in logistics hubs with continuous truck traffic.

Weather Resistance (Wind & Rain): During harsh weather, they become "shields against the elements," preventing rainwater ingress and strong wind interference. This ensures smooth loading/unloading operations and reduces the risk of moisture damage to goods.

Dust & Insect Prevention: Functioning as "clean barriers," they firmly block contaminants such as dust and insects. They are widely used in industries like food and pharmaceuticals to maintain clean and compliant internal environments.

2. The main types of dock seals and shelters

Dock seals and covers are generally categorized into three types: mechanical, inflatable, and sponge. Each has its own application scenarios and structural characteristics.

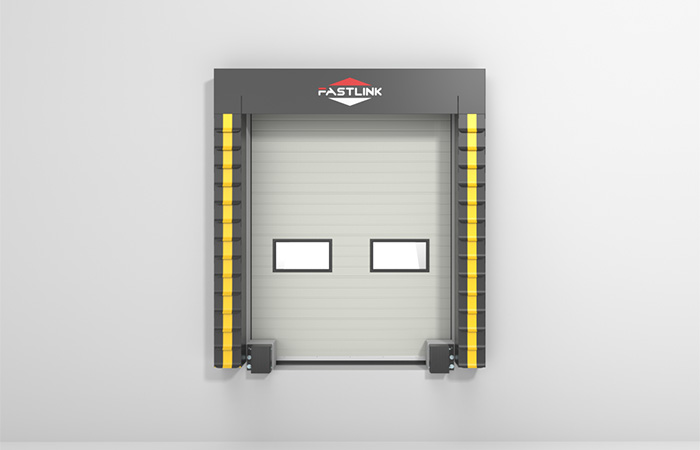

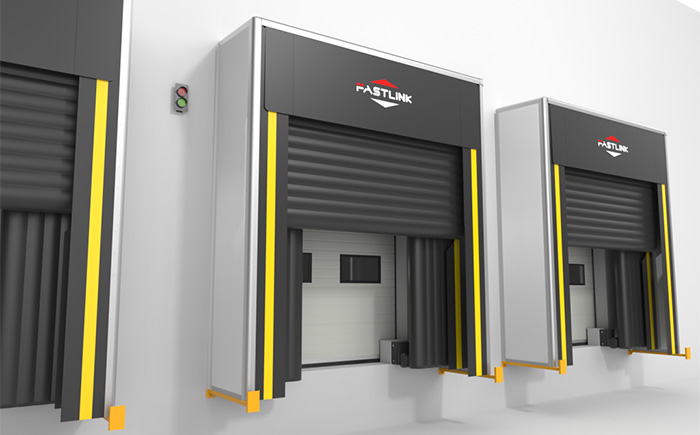

Mechanical dock shelters

The side and top panels are made of double-layer polyester fabric with PVC coating, approximately 3mm thick, offering both flexibility and strength. The frame features hinged connection arms with yellow guide strips, which act like a "navigator" to effortlessly direct vehicles in and out. Operating without external power, this robust and reliable structure offers a cost-effective solution for most common warehousing and logistics scenarios.

Sponge Dock seals

The interior is filled with high-resilience sponge, offering a compression ratio of up to 70%, with a standard thickness of 200/250mm. The sides and top are covered with wear-resistant bellows, significantly extending the product’s service life. This type of dock seal excels in environments with relatively uniform vehicle types, delivering outstanding sealing performance and strong wind resistance. It is particularly suitable for high-standard loading docks and is an ideal choice for users with demanding requirements for sealing and wind protection.

Inflatable dock shelters

The surface is made of highly wear-resistant neoprene, making it flexible and durable. The L-shaped airbags on both sides are welded using high-frequency welding, ensuring a tight fit when inflated ensuring a full seal. It automatically adapts to different vehicle models and is especially suitable for scenes with extremely high requirements for airtightness and thermal insulation, such as cold storage. It has significant energy-saving effects, and its wind resistance level can reach above level 9.

3. Typical Application Scenarios

Mechanical dock shelters: Ideal for scenarios with varying truck types and moderate sealing requirements—such as general warehouses and logistics distribution centers. It imposes minimal load on the wall structure and is easy to install, making it a true "all-rounder" solution.

Sponge dock seals: As a "precision sealing expert," it is ideal for docks with relatively consistent truck types and requires walls to have certain load-bearing capacity. With excellent wind resistance, it is a reliable choice for high-intensity and high-standard operating environments.

Inflatable dock seals: The "guardian of cold storage," they are particularly suitable for environments such as low-temperature unloading areas and temperature-controlled logistics centers. They can flexibly adapt to different vehicle types, effectively prevent temperature loss, are easy to operate, and offer outstanding winter performance.

Stop losing money and efficiency at the loading dock by choosing a wrong dock seal and dock shelter. A properly sealed dock is a safer, more energy-efficient, and more productive dock. Our durable dock seals and dock shelters provide the superior protection you need to keep your operations running smoothly, regardless of the weather. If you want to know more about our product,

click here to browse our selection and find the perfect dock seal or shelter for your business.