In the warehouse sector, a loading dock leveler is more than simply a tool—it's a lifesaver. They promote the efficiency and safety of the entire process. But picking one can be difficult if you don't know what to look for because there are a lot of various kinds of dock levelers.

We're here to provide you with a thorough guide that goes over the many kinds of loading dock levelers, their special characteristics, and how they may greatly enhance your warehouse operations. Depending on your demands, we will assist you in choosing the appropriate dock leveler to purchase.

What Is A Dock Leveler?

Understanding the concept of a dock leveler and its function in the logistics exosystem is important before we jump into the various kinds of dock levelers. In short, a dock leveler is an important machinery used to close the distance between a trailer and a loading dock. It’s not only for the convenience. Dock leveler protects the effectiveness and safety of the warehouse environment by enabling smooth docking operation and reducing the probability of accidents and product damage.

Dock levelers are engineered to fulfill the operational standards and special industrial circumstances. They come in a variety of shapes and features. In today’s warehouse industry, the dock leveler has an important role in controlling the height difference between the dock and the trailer as well as guaranteeing the smooth workflow.

Types of Dock Levelers

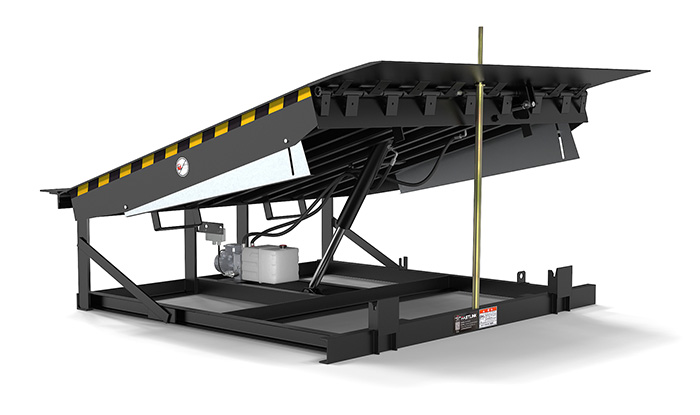

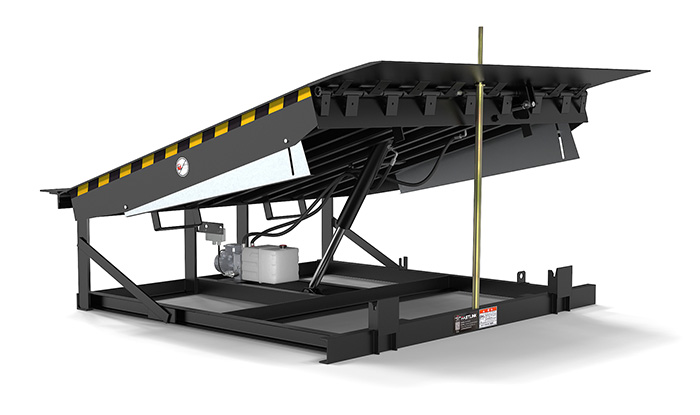

Hydraulic Dock Leveler

The dependability and user-friendliness of hydraulic dock levelers are non-questionable. They are a star for this. Hydraulic dock levelers are powered by hydraulic pump technology. This hydraulic pump will power the lip cylinders, and the leveler platform is activated by a single push button. With this, it will be smooth and automatic to move between the dock and the trailer, removing the need for manual handling for better productivity and lowering the risk of accidents.

Because of its robust design that can handle big, heavy loads and frequent use, a hydraulic dock leveler is the reliable and perfect choice for busy logistics. A hydraulic dock leveler has state-of-the-art safety features, such as automated dock level return and emergency stop buttons. These features add an extra layer of protection for the goods and the employees.

Hydraulic Dock Levelers Benefits

- Easy to Use: With one button press to adjust the hydraulic dock levelers reduce manual physical labor. This will guarantee that employees maintain their attention on more crucial duties.

- Durability: Because hydraulic dock levelers are specifically designed to withstand large, heavy loads with frequent use, they are appropriate for warehouses with high-traffic operations. Their sturdy design guarantees a longer lifespan, which lowers maintenance expenses and provides an excellent return of investment. This is a huge advantage for a business.

- Safety: Two of the safety measures provided by the hydraulic dock levelers are: emergency stop buttons and the automated dock level return. These characteristics are crucial for preventing mishaps, ensuring a secure work environment, and safeguarding both the personnel and the items.

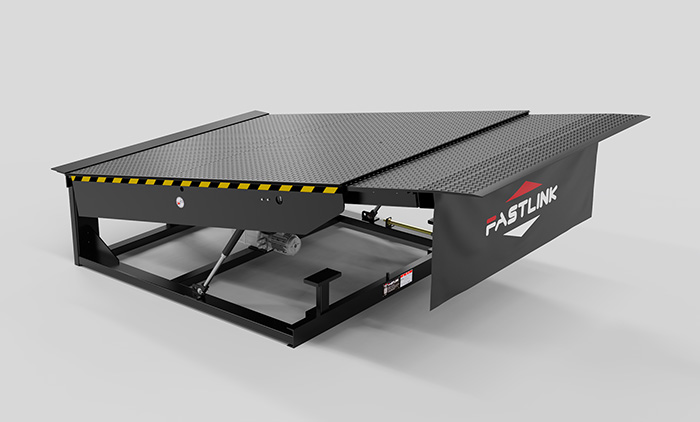

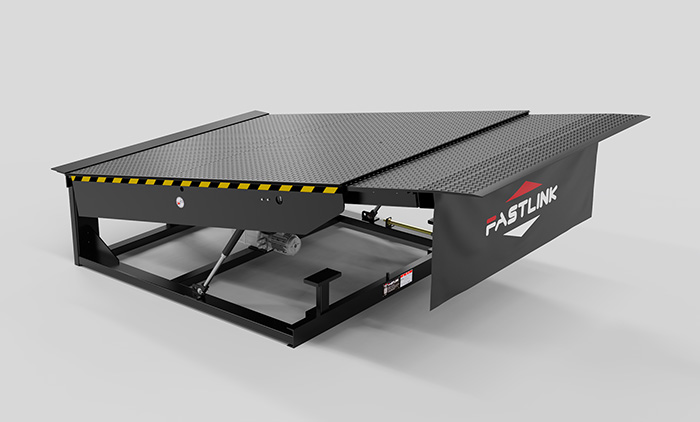

Telescopic Dock Leveler

By creating an uphill transition between the back of the vehicle and the platform, telescopic dock levelers can efficiently adjust the height difference between the bottom plate of various transport vehicles and the platform, allowing the loading and unloading process to be finished in one step while preventing unnecessary risks and accidental damage. Telescopic dock levelers can also improve logistics loading and unloading efficiency.

Telescopic Dock Leveler is a superior option for locations like cold storage that have strict sealing and insulation requirements. The cold storage insulation sliding door usually has a Telescopic Dock Leveler mounted on the inside. When the door is closed, it falls straight to the bottom of the foundation pit, preventing air from convecting between the internal and outdoor spaces. This creates a completely sealed unloading position design and lowers energy loss.

Benefits of Telescopic Dock Levelers

- Versatile Reach: The extendable lip allows for precise positioning, bridging gaps of varying lengths between the dock and the truck. This makes them ideal for facilities handling diverse vehicle types and those requiring exact alignment for loading and unloading.

- Enhanced Sealing and Insulation: Telescopic levelers are excellent for environments like cold storage. Their design enables a tight seal that will significantly reduce air convection and energy loss, which is critical for maintaining specific temperatures.

- Optimal for Specific Operations: There will be such specific situations where the trailer may not always back up precisely, or when dealing with trailers that have varying bed heights. In those kinds of situations, a telescopic leveler provides the flexibility to ensure a smooth and safe transition.

Choosing the right dock leveler

- Load capacity: When calculating the load capacity, the maximum weight of the goods or products must be considered. This guarantees that the dock leveler can sustain your heaviest load without wear or damage, which is crucial for safety. In addition to its weight, you also need to consider the amount and the volume of the items that are being docked. Once you have all the information, consult this with the dock leveler provider, and they will suggest you a suitable dock leveler.

- Operational needs: What kinds of trailers will you be using? And how frequently will you utilize them? Telescopic levelers may be more suitable for specialized tasks, like those involving different kinds of trucks or cold storage. While high-traffic docking operations can benefit from the speed and automation of a hydraulic system.

- Space restrictions: Assess the amount of space at your loading dock that is available. Some dock leveler types might require more pit depth or approach space than others.

Choosing the right dock leveler is key to warehouse efficiency and safety. Knowing the difference between telescopic and hydraulic dock levelers will help you decide what’s best for your business. Although both types operate exceptionally well, the best option will always depend on the particular needs of your site. Remember to consider load capacity, operational requirements, and space restrictions when choosing your dock leveler.

Investing in the right dock leveler means your staff will work in a safer environment and your warehouse will perform better. Now you’re ready to choose the best for your company’s dock equipment needs and smooth logistics operations that will support your business growth. To ensure that you select the best dock leveler for your site,

get in touch with us to schedule a call or a visit with a member of our knowledgeable staff, or

explore our entire selection of dock levelers here.