High-Speed Opening and Closing

Ordinary cold storage doors open relatively slowly. This not only limits loading/unloading efficiency but also means the door is unsuitable for frequent cycling, leading to operational issues. Especially during peak loading/unloading periods, ordinary doors often need to remain open for extended times, causing significant energy loss. This also leads to substantial temperature fluctuations inside the storage room. Repeated temperature swings cause moisture in the air to condense inside the storage space, potentially leading to widespread ice formation. This can impact equipment operation and pose a potential threat to stored goods’ quality.

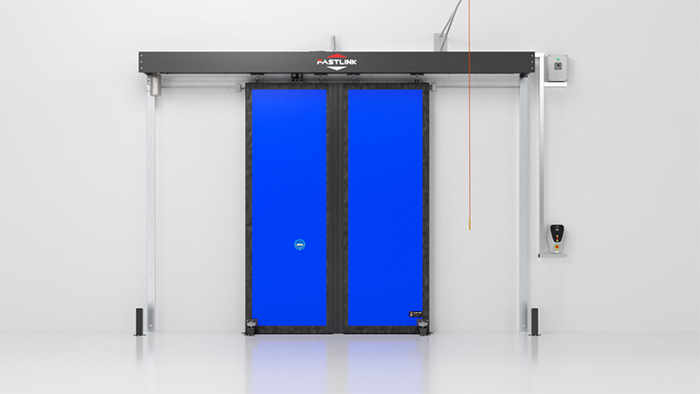

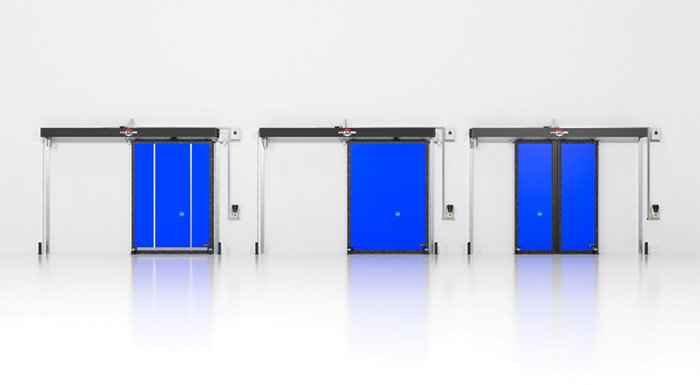

The Fastlink Cold Storage High Speed Sliding Door represents a qualitative breakthrough in speed. A single door leaf achieves an opening speed of up to 2.5 m/s. With a dual-leaf design, opening time can be halved again. Practical tests show its cycling speed is over four times faster than ordinary cold storage doors. Furthermore, this door features a shorter delay before closing, minimizing the total time the door remains open. This effectively blocks cold air loss and hot air ingress, reducing cold air leakage at the source and providing reliable assurance for lowering energy consumption in cold storage operations.

Impact Resistant and Durable

Ordinary cold storage door panels typically use a polyurethane-stainless steel or color steel composite structure. As daily cold storage operations rely on frequent forklift traffic for moving goods, the fast-paced workflow makes collisions between forklifts and the door highly likely. Rigid door panels lack buffering and self-recovery capabilities. Once impacted, they often suffer dents, warping, and other deformations, which are generally irreparable. This not only incurs additional costs for replacement panels but also leads to cold air leakage due to compromised door seal integrity, disrupting normal cold storage operation.

Fastlink's new cold storage door, utilizing a third-generation waterproof insulated core material paired with a flexible surface panel, changes this situation. Its door panel abandons the traditional rigid structure design. The flexible panel can absorb impact energy through deformation upon forklift collision and automatically returns to its original shape once the force is removed. This effectively protects the structural integrity of the door, avoids the hassle of frequent repairs and replacements, and consistently maintains excellent sealing and thermal insulation performance, providing more stable and reliable protection for cold storage operations.

Sealing and Thermal Insulation

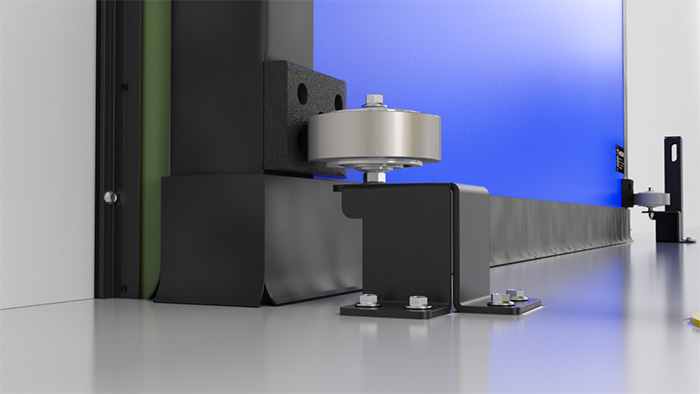

The Fastlink Cold Storage High Speed Sliding Door uses a third-generation waterproof insulation material for its panel, achieving ten times the thermal insulation efficiency of ordinary rapid doors. For example, the 100mm thick third-generation waterproof insulated panel has a thermal conductivity of just 0.032 W/(m·K). Its superior insulating properties allow a single door to operate stably in low-temperature freezing environments down to -25°C, effectively blocking cold air loss and heat ingress, fundamentally resolving issues of door condensation and frost formation. The door’s bottom structure, made of multi-layer PVC-coated polyester material, is paired with an adjustable rubber sweep seal. This allows real-time adjustment of ground contact based on the cold room floor's flatness, sealing the path for cold air loss downwards from the source and completely avoiding cold leakage due to poor bottom sealing. The track is equipped with a heating function to prevent frost formation on it. The Armor Lock™ positioning armor focuses on reinforcing the seal around the entire door perimeter, creating a stringent sealing effect. This not only blocks convective air heat transfer and associated cold loss but also effectively prevents the infiltration of external moist, hot air.

Efficient and Intelligent

Fastlink's self-developed, integrated intelligent control system is equipped with an LED touchscreen rated IP65, suitable for a damp, low-temperature cold storage environment. It features a cycle count and fault code display for easy maintenance. If the motor drive wires are connected incorrectly, the system reports an error and stops the door, providing directional protection. It has a memory function after power loss; following manual operation, it resets automatically upon power restoration without needing readjustment. The motor includes overload and overcurrent protection, features an integrated wiring harness design, and incorporates IoT functionality.

From rapid cycling to reduce cold loss to the flexible panel resisting impact damage, from the third-generation insulation material strengthening the thermal barrier to the precise sealing design blocking leakage paths, and the intelligent control system ensuring stable operation, the Fastlink Cold Storage High Speed Sliding Door addresses numerous pain points of traditional doors with its multi-dimensional performance advantages. It not only helps companies reduce operational costs by lowering energy consumption but also enhances cold storage operational efficiency and temperature stability through reliable performance, safeguarding the quality of stored goods. In the current era of rapid development in the cold chain industry, the Cold Storage High Speed Sliding Door is undoubtedly set to inject powerful momentum into future progress.