I. Standard Operating Procedures

Correct operation is the foundation for the safe and stable performance of the equipment. Please follow the steps below:

- Opening the Door: When access is required, press the "OPEN" button on the controller. The door will begin to open. If partial opening is sufficient, press the "STOP" button to halt the door immediately. This design balances efficiency with flexibility.

- Closing the Door: After operations are complete, press the "CLOSE" button. The door will close smoothly to ensure effective environmental isolation.

- Emergency Stop: Safety is paramount. During door movement, if any abnormality is detected (e.g., an obstacle, unusual noise), immediately press the red "EMERGENCY STOP" switch. This is the most critical safety measure for sudden situations, causing the door to halt instantly in its current position.

II. Core Safety Precautions

Safety is no trivial matter. This equipment operates at high speeds, and any negligence may result in serious injury. Please keep the following points in mind:

- Maintain a Safe Distance: The door possesses significant kinetic energy while moving at high speed. Personnel and vehicles must always maintain a safe distance. It is strictly forbidden to attempt to pass through while the door is in motion to prevent impact, crushing, or other serious accidents.

- No Lingering in the Doorway: This door features an automatic closing function. Absolutely prohibit lingering or placing objects within the door's path to prevent accidents during closure.

- Use Designated Controls Only: This automated door must only be operated via the dedicated controller or optional automated devices (e.g., motion sensors, pull-cord switches). Manually forcing the door open or closed is strictly prohibited, as this can easily lead to door panel deformation, track damage, and personal injury.

- Proper Use of Door Locks: The handle and lock on the door panel are designed for emergency egress or rescue access. Under normal circumstances, do not touch or use them to ensure the proper operation of the automated door system.

III. Equipment Maintenance and Access Control Management

Standardized maintenance and strict access control are crucial for the long-term, reliable operation of the equipment.

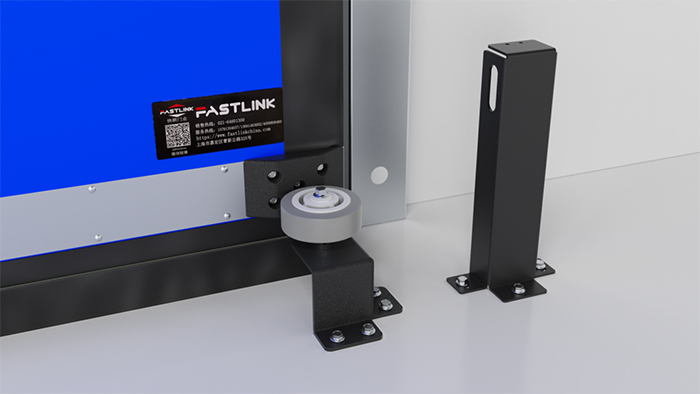

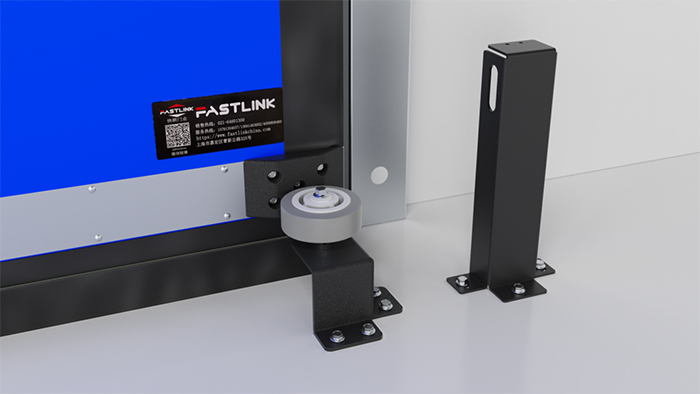

- Regular Inspections: Conduct periodic inspections of the door panel, wear-prone parts, and other key components. If any signs of wear, looseness, damage, or functional failure are detected, you must immediately stop using the door and contact qualified personnel for repair or replacement.

- Qualified Personnel for Service: All maintenance and servicing tasks, especially those involving electrical components, must be performed by professional technicians. Unauthorized repairs or disassembly by unqualified personnel will not only cause equipment damage but also create serious safety hazards.

- No Unauthorized Parameter Changes: Arbitrary modification of parameters within the drive controller is prohibited. Incorrect parameter settings are a primary cause of equipment malfunction, performance degradation, and even complete failure.

- Guard Against Electric Shock Risk: After the drive is powered on, high voltage may be present within the drive and its surrounding circuits, regardless of whether the door is moving. Do not touch the drive or its circuitry while power is applied to prevent the risk of electric shock.

Conclusion

Safety is not merely a set of rules but a profound sense of responsibility and a consistent behavioral habit. For the Cold Storage High Speed Sliding Door, correct operation and meticulous maintenance are not just about protecting the equipment; they represent respect for energy efficiency, cargo integrity, and, most importantly, human life. Let us work together to fortify our safety defenses, ensuring that efficiency and safety are perfectly realized with every cycle of the door.